Task III.C - Operation of Systems 11 - Deicing and Anti-Icing

Lesson Overview

Objective

The student should know PA-28-151 anti-icing limitations, practices, and applications

Reference

-

Piper Warrior PA-28-151 POH

-

CFR 14

-

AFH

Key Elements

-

Outlook

-

Recognition

-

Implications

Elements

-

Aerodynamics of Icing

-

Avoiding Icing Conditions

-

Types of Icing

-

Recognizing Icing Conditions

-

Three Types of PA-28-151 Anti-Icing Systems

-

Instruments and Plane Reactions to Icing

-

Anti-ice Systems Insufficient

Equipment

-

Whiteboard and Marker

-

Pictorial Representations

-

References

Schedule

-

Context

-

Specific PA-28-181 Icing Threats and Remedies

-

Conclusion and Recommendations

Instructor Actions

-

Discuss lesson objectives with student

-

Present the lecture

-

Answer questions the student has

Student Actions

-

Listen to presentation

-

Take notes on the lesson

-

Ask questions if further explanation is needed or just curious

Completion Standards

The student understands the environmental system and its operations in a Standards Piper Archer.

Instructor Notes

Introduction

-

Review objectives and elements/key ideas

Ice - Aerodynamics

Wing Stalls

Note: See reference above for NASA information on icing and additional content to learn more about structural icing

An ice-contaminated wing will stall at a lower angle of attack or higher airspeed than a clean wing. Minute amounts of ice (equivalent to medium grit sandpaper) covering the leading edges or upper surfaces of wings can increase the stall speed up to 15 knots.

Ice on the wing also can disrupt the airflow over the ailerons and cause the aircraft to behave in unusual ways. The aileron may deflect without pilot input and cause an uncommanded roll.

Tail Stalls

In most aircraft designs, the center of gravity is forward of the wing center of lift. The two forces at these two points generate a nose-down pitch. The horizontal stabilizer counter-acts this nose down moment by generating downward lift.

To generate downward lift, the horizontal stabilizer acts like an upside-down wing. Consequently, to prevent a tail stall, the air flow must stay attached to the lower surface of the tail, just as the flow must stay attached to the upper surface of the wing to prevent a wing stall.

Ice contaminated tail stalls are almost always associated with flap extension. Lowering the flaps increases the wing downwash, and thereby greatly increases the horizontal stabilizer’s angle of attack. Increasing speed and thrust can also increase the angle of attack at the horizontal stabilizer.

Increasing tailplane angle of attack with ice on the tail can disrupt the airflow under the stabilizer and make the elevator less effective. The elevator may oscillate without pilot input and cause an uncommanded pitch change.

In extreme cases, the yoke might snatch forward, immediately pitching the nose down.

-

Wing stalls usually occur at slower airspeeds or following premature flap retraction.

-

Tail stalls almost always occur with flap extension, or at the high speed limit for flap extension.

Types of Icing

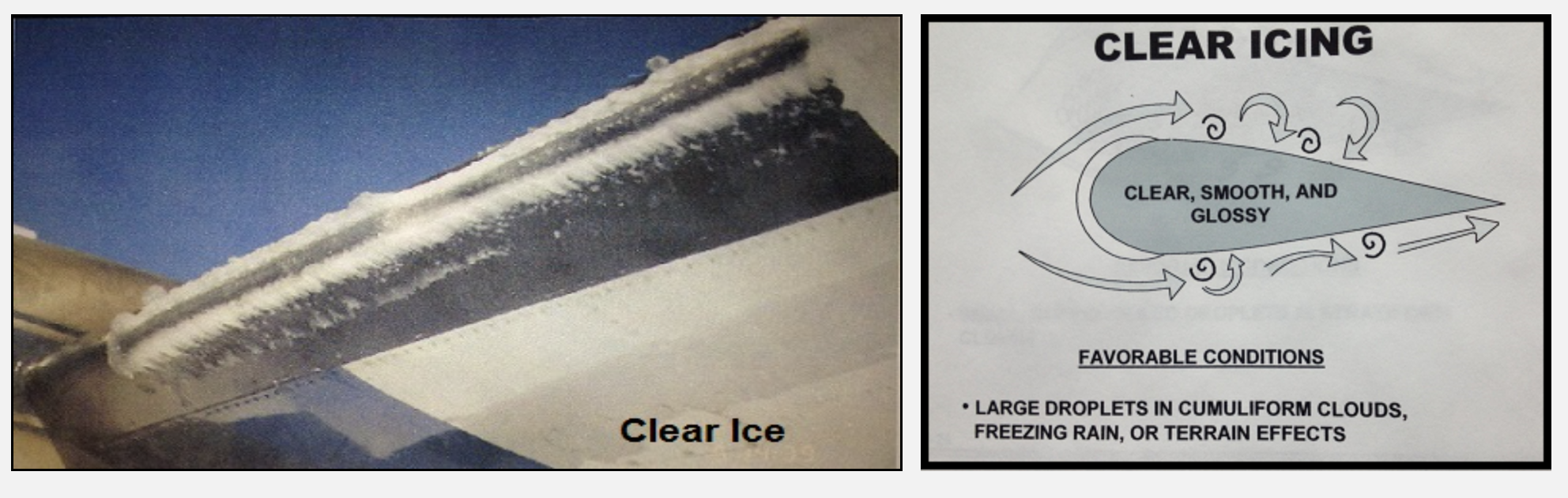

Clear Ice

Clear ice or glaze ice is a heavy coating of glassy ice which forms when flying in areas with high concentration of large supercooled water droplets, such as cumuliform clouds and freezing rain. It spreads, often unevenly, over wing and tail surfaces, propeller blades, antennas, etc. Clear ice forms when only a small part of the supercooled water droplet freezes on impact. The temperature of the aircraft skin rises to 0°C with the heat released during that initial freezing by impact of the part of the droplet. A large portion of the droplet is left to spread out, mingle with other droplets before slowly and finally freezing. A solid sheet of clear ice thus forms with no embedded air bubbles to weaken its structure. As more ice accumulates, the ice builds up into a single or double horn shape that projects ahead of the wing, tail surface, antenna, etc. on which it is collecting. This unique ice formation severely disrupts the airflow and is responsible for an increase in drag that may be as much as 300 to 500%.

The danger of clear ice is great owing to (1) the loss of lift, because of the altered wing camber and the disruption of the smooth flow of air over the wing and tail surfaces, (2) the increase in drag on account of the enlarged profile area of the wings. (3) the weight of the large mass of ice which may accumulate in a short time, and finally (4) the vibration caused by the unequal loading on the wings and on the blades of the propeller(s). When large blocks break off, the vibration may become severe enough to seriously impair the structure of the airplane. When mixed with snow or sleet, clear ice may have a whitish appearance. (This was once classified as rime-glazed but it is now considered to be a form of clear ice).

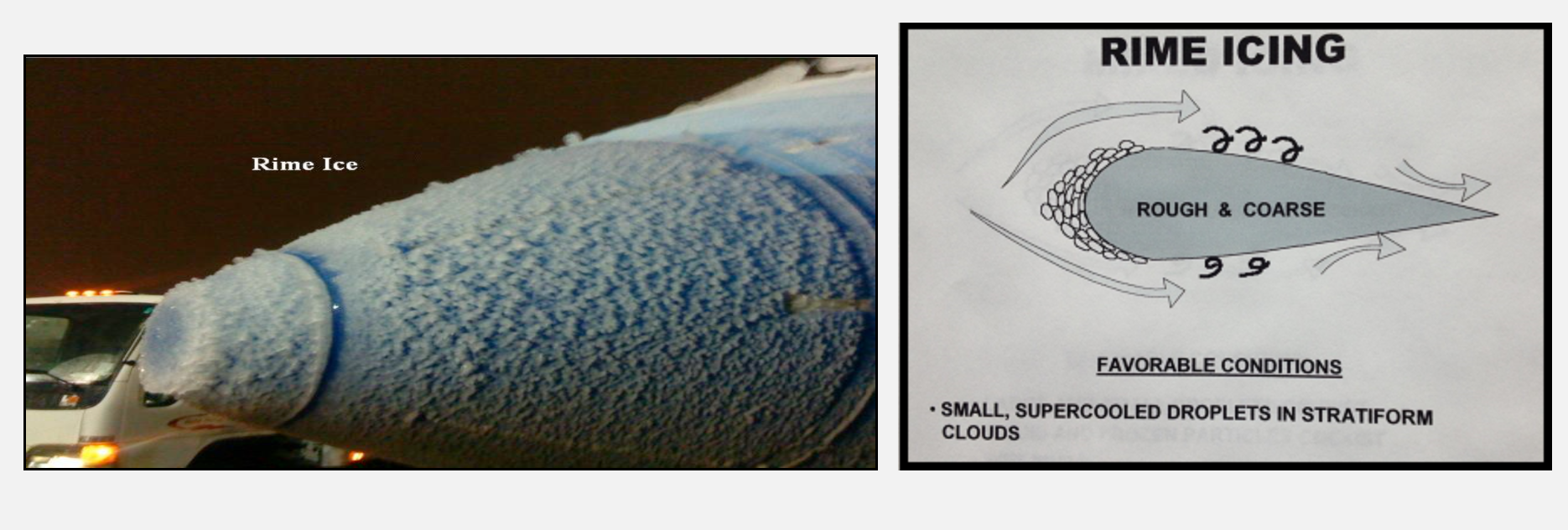

Rime Ice

Rime ice is an opaque, or milky white, deposit of ice that forms when the airplane is flying through filmy/stratiform clouds. It is dependent on a low rate of catch of small supercooled water droplets. It accumulates on the leading edges of wings and on antennas, pilot heads, etc. For rime to form, the aircraft skin must be at a temperature below 0°C. The drop will then freeze completely and quickly without spreading from the point of impact. Thus, the droplets retain their spherical shape as they freeze, creating air packets between the frozen particles. This process creates an irregular shape of the ice.

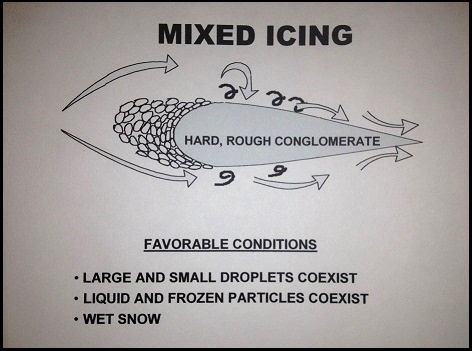

The deposit has no great weight, but its danger lies in the aerodynamic alteration of the wing camber and in the choking of the orifices of the carburetor and instruments. Rime is usually brittle and can easily be dislodged by de-icing equipment. Occasionally, both rime and clear ice will form concurrently. This is called mixed icing and has the bad features of both types.

MIXED ICE

Mixed icing, as the name implies, has the properties of both clear and rime icing. Large and small supercooled droplets coexist. Appearance is whitish, irregular and rough. Favorable conditions include liquid and frozen particles found in the colder portion of the cumuliform cloud and wet snow flakes. The formation process for mixing icing includes that of clear and rime icing. Mixed ice can accumulate rapidly and is difficult to remove.

| |

|  | |----|---|

| |----|---|

Frost

A white semi-crystalline frost which covers the surface of the airplane forms in clear air by the process of deposition. This has little or no effect on flying but may obscure vision by coating the windshield. It may also interfere with radio by coating the antenna with ice. It generally forms in clear air when a cold aircraft enters warmer and damper air during a steep descent. Aircraft parked outside on clear cold nights are likely to be coated with frost by morning. The upper surfaces of the aircraft cool by radiation to a temperature below that of the surrounding air.

Frost which forms on wings, tail and control surfaces must be removed before take-off. Frost alters the aerodynamic characteristics of the wing sufficiently to interfere with take-off by increasing stall speed and reducing lift. Frozen dew may also form on aircraft parked outside on a night when temperatures are just below freezing. Dew first condenses on the aircraft skin and then freezes as the surface of the aircraft cools. Frozen dew is usually clear and somewhat crystalline, whereas frost is white and feathery. Frozen dew, like frost, must be removed before take-off. In fact, any snow or moisture of any kind should be removed since these may freeze to the surface while the airplane is taxiing out for take-off. The heat loss due to the forward speed of the airplane may be sufficient to cause congelation.

Rules to Follow

To avoid icing problems, here are a few rules to follow:

-

Avoid flight into an area where icing conditions are known to exist. Do not fly through rain showers or wet snow when the temperature is near 0°C. Do not fly into cumulus clouds when the temperature is low.

-

Always consult a weather office or flight service station to obtain a forecast about expected icing conditions before taking off on any flight in fall or winter.

-

Icing in freezing drizzle is usually maximum just below the cloud base where the drops are largest. Icing is of the clear ice type.

-

Snow and Ice Crystals colder than -20°C do not adhere to cold aircraft and do not usually constitute an icing problem. However, if the aircraft is warm, the snow may melt as it strikes the warm surface and ice accretion may result. If supercooled water droplets are also present with the snow, a rapid build up of rough ice can occur.

Icing Avoidance

Few single engine airplanes, or even light twin-engine types incorporate any means of ice prevention. A few tips for pilots flying airplanes in this category will therefore be in order.

When ice formation is observed in flight, there is only one certain method of avoiding its hazards and that is to get out of the ice-forming layer as quickly as possible. This may be done by climbing above the ice forming zone. This alternative would obviously require an airplane that has good performance and is fitted with radio and proper instruments for flying over the top. The next alternative would be to descend and fly contact below the ice forming zone. The advisability of this course would depend on the ceiling and visibility along the route at the lower level concerned.

Do not remain in icing conditions any longer than necessary. For that reason, during climbs or descents through a layer in which icing conditions exist, plan your ascent or descent to be in the layer for as short a time as possible. However, keep your speed as slow as possible consistent with safety. Speed of an airplane affects accretion of ice. The faster an airplane moves through an area of supercooled water drops, the more moisture it encounters and the faster will be the accumulation of ice.

If ice has started to build up on the airplane

-

Do not make steep turns or climb too fast since stalling speed is affected by ice accumulation.

-

Fuel consumption is greater due to increased drag and the additional power required.

-

Land with more speed and power than usual.

-

Do not land with power off!!

-

Protecting from Icing

Many modern airplanes that are designed for personal and corporate use, as well as the larger transport type airplanes, are fitted with various systems designed to prevent ice from forming (anti-icers) or to remove ice after it has formed (de-icers).

-

Fluids. There are fluids which are released through slinger rings or porous leading edge members to flow over the blades of the propellers and the surfaces of the wings. A fluid is an anti-icing device since it makes it difficult for ice to form.

-

Rubber Boots. Membranes of rubber are attached to the leading edges. They can be made to pulsate in such a way that ice is cracked and broken off after it has already formed. This is a de-icing device.

-

Heating Devices. Heating vulnerable areas is a method for preventing the buildup of ice. Hot air from the engine or special heaters is ducted to the leading edges of wings, empennages, etc. Electrically heated coils protect pilot tubes, propellers, etc.

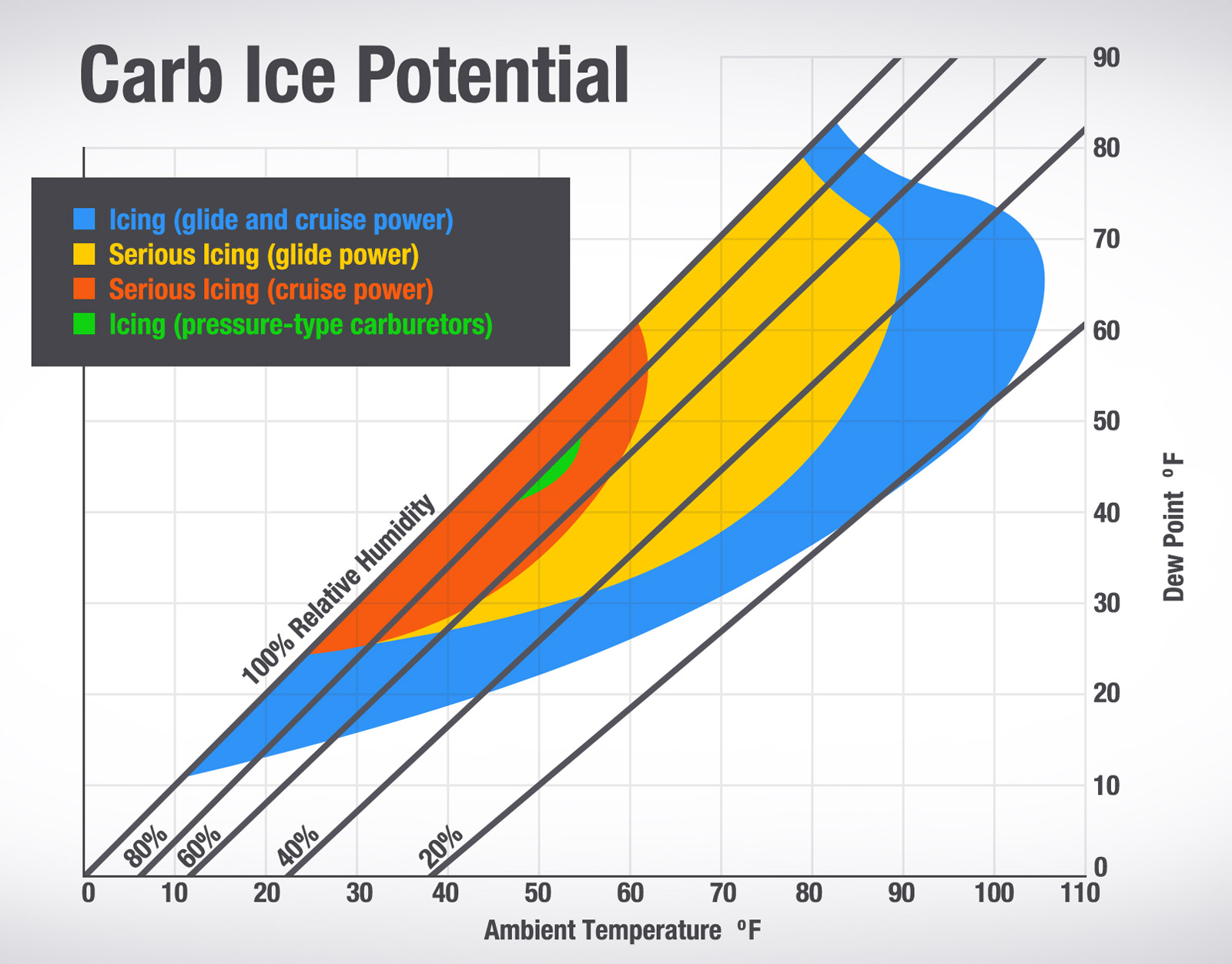

Icing Protection on the Warrior PA28-151

You can pickup Carb ice in Florida, even in Florida during the Summer.

-

Carb Heat - Warm air being vented into the exaust, melting any carb ice.

-

We have a JPI-930 monitor that warns us of icing conditions in the carborator.

-

Look for RPM drop or a slow decrease in manifold pressure / % Power.

-

image::img/Carb_Ice.jpg[Carb Ice2]

-

If carburetor icing is suspected, use carburetor heat and adjust mixture for maximum smoothness (one minute max)

-

The induction air box incorporates a manually operated two-way valve

-

Allows the carburetor to receive either induction air which passes through the air filter or heated air which bypasses the filter

-

Carburetor heat also allows selection of an alternate source of air in the event the induction air source or the air filter becomes blocked with ice, snow, freezing rain, etc.

-

Carburetor heat selection provides air which is unfiltered; therefore, it should not be used during ground operations when dust or other contaminants might enter the system

-

The primary induction source should always be used for takeoffs

-

-

Defrost

-

Used with vented air that is pushed over the heater-shroud and vented into the cabin through flapper-valves.

-

-

Pitot Heat - a heated coil, dependant on the electrical system of the airplane (A high amperage device, keep this in mind if having electrical issues on plane such as a failed alternator).

-

Prevents problems with icing or heavy rain

-

The pitot heat system has a separate circuit breaker

-

The operational status of the pitot heat system should be included in the preflight check.

-

Do not operate when above 10C or not in IMC (unless there’s a reason to suspect ice blockage). The coil will burn up if run continuously on the ground.

-

-

Alternate static source

-

Located below the left side of the instrument panel

-

When the valve is set in the alternate position, the altimeter, vertical speed indicator, and airspeed indicator will be using cabin air for static pressure

-

The storm window and cabin vents must be closed and the cabin heater and defroster must be on during the alternate static source operation

-

The altimeter error is less than 50 feet unless otherwise placarded

-

Alternative Protection / Precautions

-

Pre-wipe plane before takeoff if moisture is on the plane and flying in or near freezing temps.

-

A towel wiping down the wing is worth more than 10 gallons of anti-ice fluid.

-

-

Planning! Using the resources from the FAA and technical resources.

-

Flight icing levels / Foreflight / Weather Brief

-

You the Pilot! You are the most important anti-ice equipment on the aircraft.

Most important anti-ice equipment is the pilot! Your decisions you make on the ground is more important than the equipment in the plane for avoiding danger.

Aircraft Reaction to Icing

Tail stall

-

Aircraft will pitch down if the tail stalls

-

Must recover with back elevator, increasing airspeed, and reducing flaps, decreasing power slightly

Wing stall

-

Aircraft will buffet

-

Must recover with forward pressure and increasing airspeed Carburetor icing / induction icing

-

Aircraft will run rough

-

Must recover by using carb heat (max one minute) and adjusting mixture

Pitot icing

-

Air speed indicator will read zero if the ram air is open and pitot blocked

-

Air speed indicator will indicate an increase in airspeed during climb if ram air is blocked too (mimics altimeter)

-

Recover by turning on pitot heat

Static source icing

-

Altimeter will freeze, VSI will go to zero, and airspeed indicator will have an error where air speed will read lower at higher altitudes and higher at lower altitudes (reverse altimeter)

Static source and pitot icing

-

Altimeter and airspeed indicator will freeze and VSI will freeze and drop to zero

-

Why is this dangerous? Discuss Air France 447 Crash - Brazil

-

Icing Systems are insufficient

-

If there is an issue with one system on the aircraft, you may have icing problems in other areas too (unless carb ice is the only issue)

-

It is imperative to get out of a situation where ice is accumulating

-

Climb, descend, or turn around to avoid escalating an icing situation to a point of no return

Conclusion

Questions for Student

-

What actions will you take if you are flying in IMC and your airspeed reads zero?

-

What actions will you take if your altimeter seems to be frozen?

-

Will you fly with a small amount of frost on the wings?

-

What actions will you take if you hear the stall warning horn in IMC?

ACS Requirements

To determine that the applicant exhibits instructional knowledge of the elements of principles of flight by describing:

-

Primary and secondary flight controls

-

Trim

-

Powerplant and propeller

-

Landing gear

-

Fuel, oil, and hydraulic

-

Electrical

-

Avionics including autopilot

-

Pitot static, vacuum/pressure and associated instruments

-

Environmental

-

Deicing and Anti-icing.